I wish all jobs always went according to the original planning, but, as we all know, it’s never happening. This one was a classic example. It came to my shop in a pretty rough shape, the parts were unfinished, the dust cover had multiple holes drilled and tapped for previous scope mount installations and the magwell was nearly beaten to death.

The first thing to do was to plug the existing holes so that I can drill new ones for the new scope mount. I made a length of threaded rod from a mild steel, cut it into pieces and silver soldered to the frame, then filed everything down, then drilled and tapped for the new mount. So far so good.

The customer wanted a black and gold color pattern so I got some Midnight Blue and some Gold Cerakote and painted everything. Again, no issues here.

And only after I started putting the gun together I realized that the scope mount sits too low and doesn’t have enough clearance for the slide. A quick conversation with the customer (who ordered that particular scope mount) revealed that the mount is specifically designed for flat top slides! Hmm, ok, time to get busy with my milling machine…

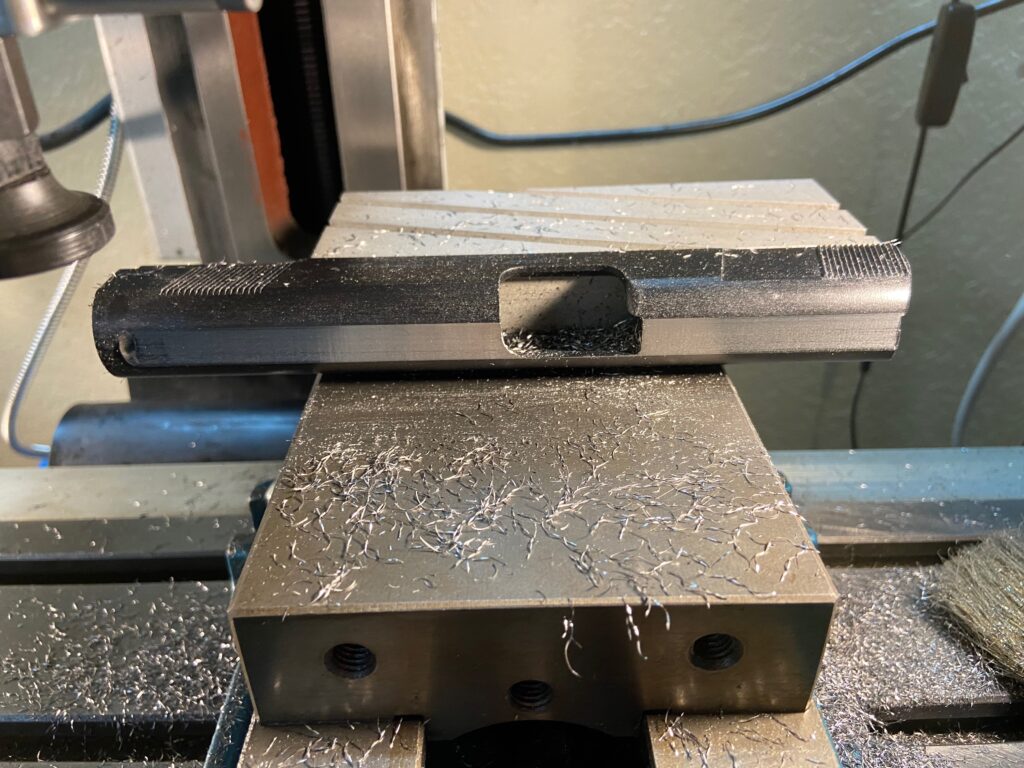

It took me a while to properly indicate the slide. The slide top was not straight, it had quite a few low spots, so even though the vise was indicated square, the slide still wasn’t, so I spent quite a bit of time going back and forth until it was reasonably square. Then I started taking shallow passes with 3/8″ endmill until the flat has established, and then I kept taking .005″ at each pass until .040″ total of material was removed.

Then I made a few serrations with a 60 degrees double angle cutter. The gun doesn’t have iron sights, so the serrations are purely cosmetic as there’s no need to reduce the glare. Most portion of the slide is covered by the scope and mount anyway.

The slide then was cleaned and repainted and the gun finally was assembled. And since I had to re-indicate the vise again, I took it off and spent the rest of my day giving my mill some much needed cleaning and maintenance.