A fellow club member asked me to tune up his gun. It was not cycling properly and hanging up on disconnector every now and then, and after a brief inspection we decided that a Marvel disconnector cut will help. For those of you who have never heard this term before, it’s the angle cut on the disconnector rail of the slide, which eases the disconnector down as opposed to plunging it down into the frame abruptly.

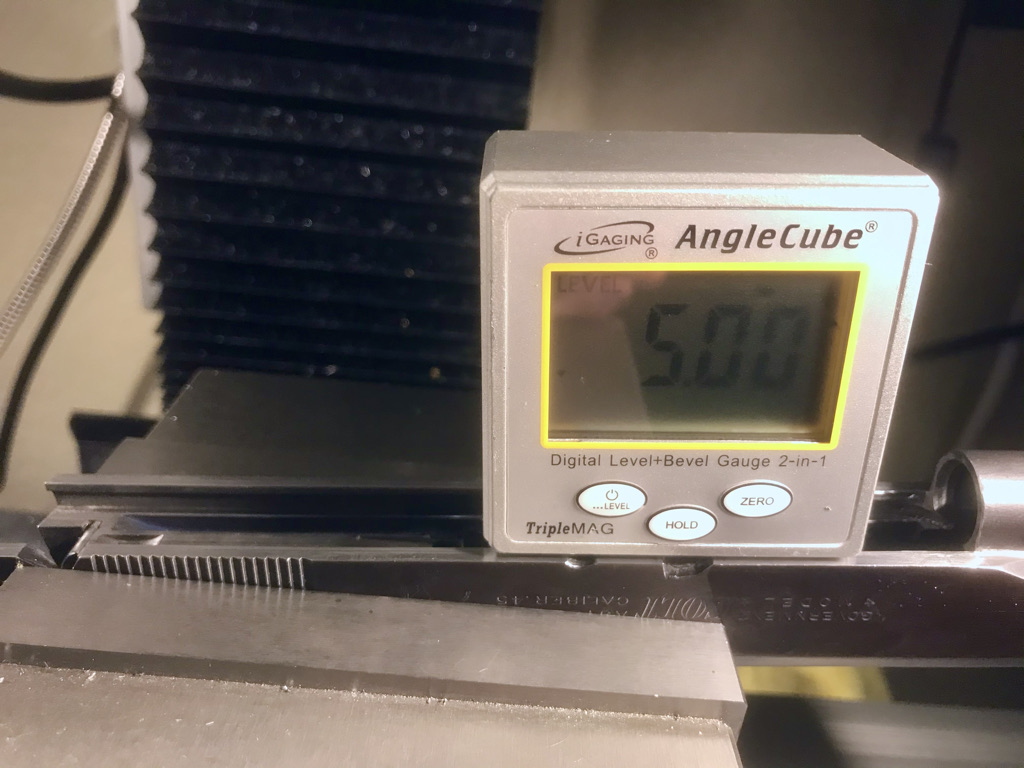

Making this cut is fairly easy. I secured the slide upside down in my vise and put my AngleCube on top of it and moved it up and down until it showed 5 degrees. Then I came in with an 11/64 end mill, touched off the edge of the disconnector rail and zeroed the Z axis. Then I started making light passes gradually until the cut was about .05 deep at the breech face.

Note that the slot is not perfectly centered on the rail, it follows the path that the disconnector actually travels.

I then rounded and polished the disconnector head and reassembled the gun. Much better now!

What machine are you using and do you have it going up 5 or down 5 when cutting slide

Wow, that’s an old post you found 🙂 The machine is Precision Matthews PM-25MV, it’s a benchtop machine, not very powerful, but ok for small work like this.

The slide is held in the vise at 5 degrees angle, so the cutter just travels horizontally left to right and back. I touch it off the highest point and make light cuts, maybe 10 thou at a time.