A club member brought me a no-name GI-style 1911 made in Philippines and asked to rebuild it as a ball gun suitable for the CMP service pistol EIC matches.

This project reminded me of the old European folk tale Stone Soup. Pretty much every single part of the gun needs to be replaced. Even the mag catch lock was badly abused by a previous owner and needs to go. Oh well, at least we can reuse the frame (even though it seems to be out of spec) and slide (but slide needs to be cut for BoMar sights and refinished).

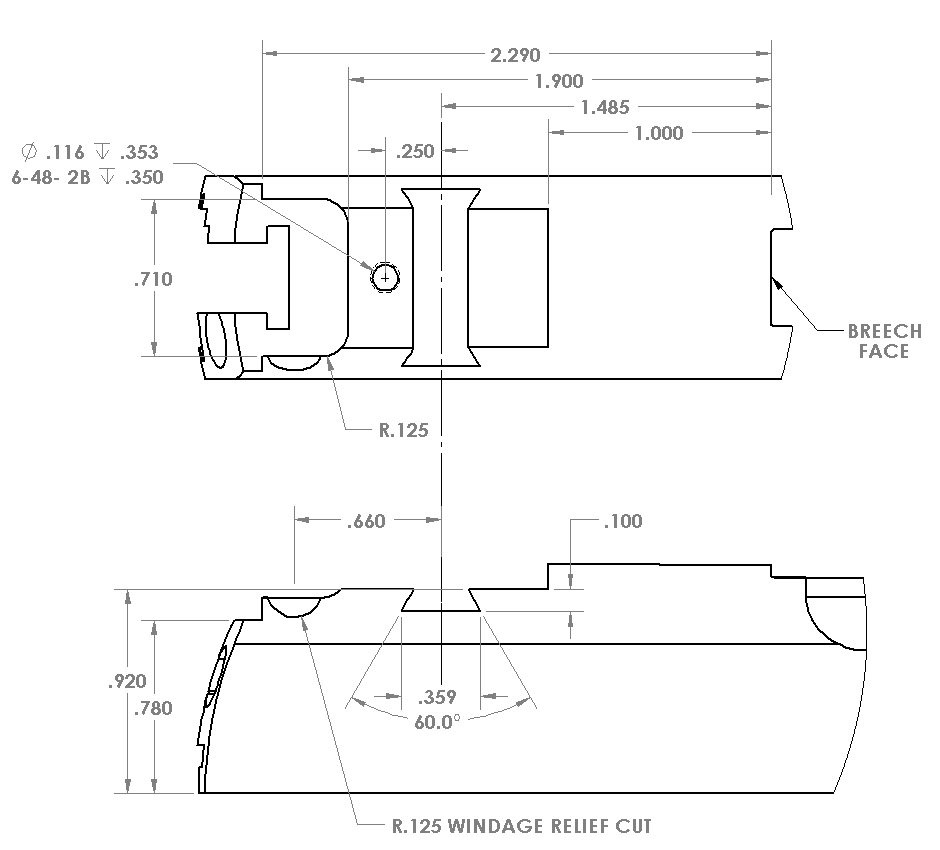

I started with cutting the slide for BoMar sights. KenSight has a drawing but it’s just for reference, because all slides are different. Still, it’s better than nothing.

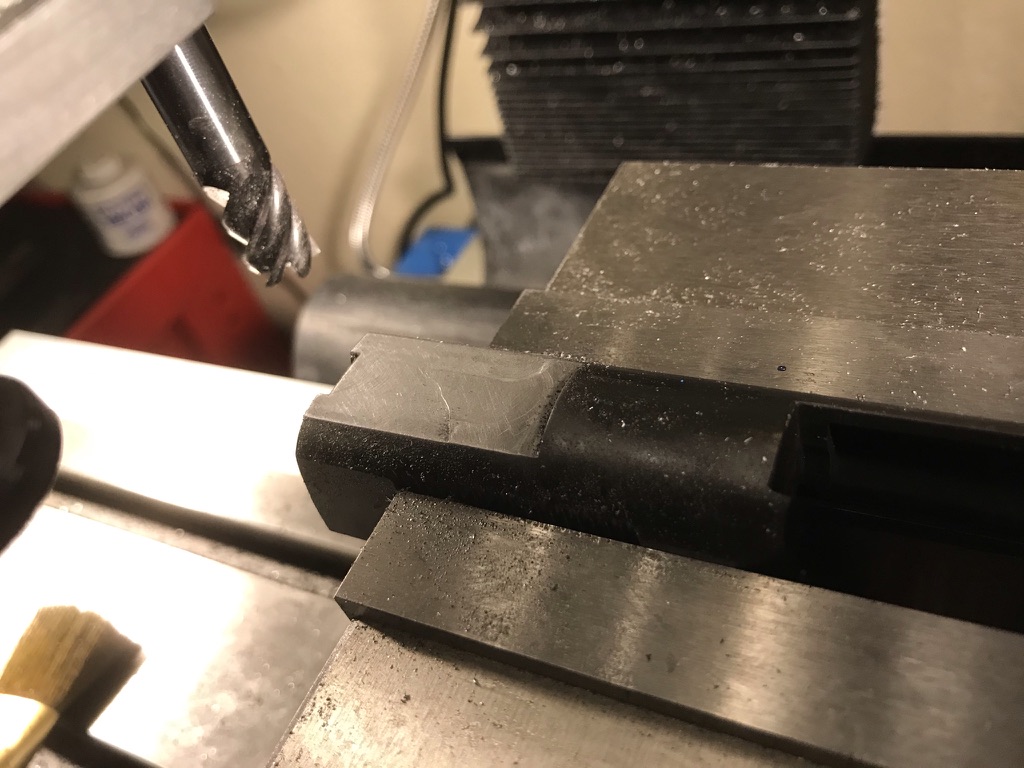

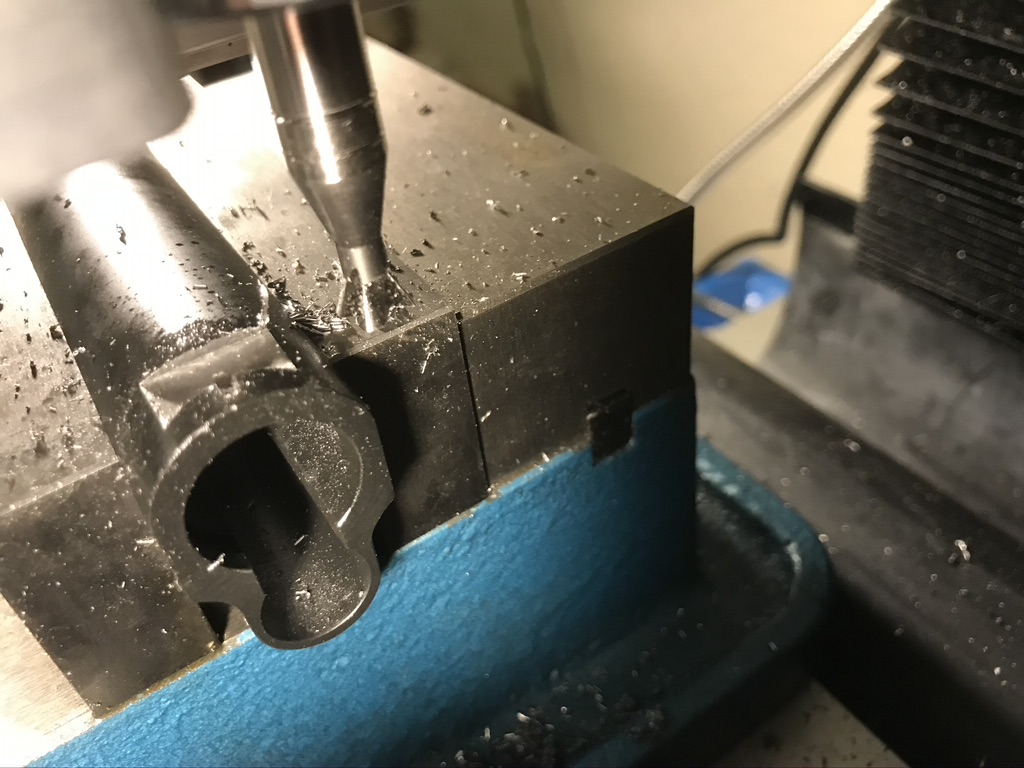

The vertical measurement on the drawing is from the bottom of the rail, so I measured the thickness of the slide and subtracted .920″, indicated off of the top and came down about .103″. I took three passes with my carbide 7/16″ end mill and the first cut was done.

Now it’s time for the 1/4″ end mill which I’m going to use for the rest of the machining. I came down another .140″ and milled the pocket for the blade.

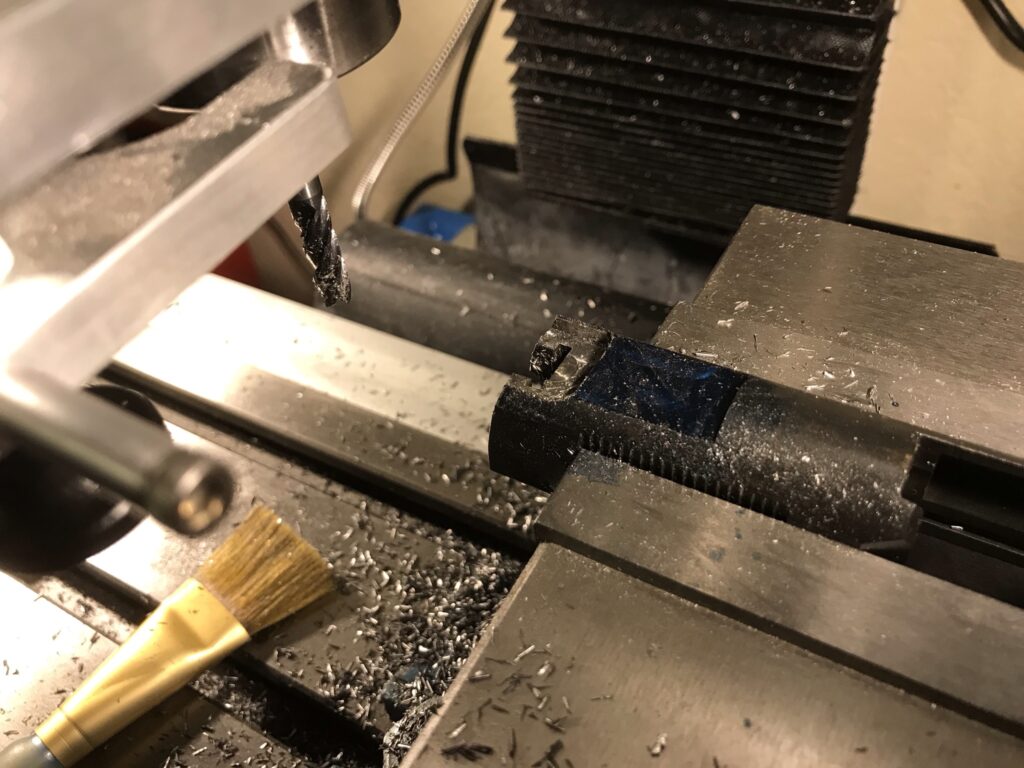

The last operation was to machine the dovetail. I started with .100″ deep channel across the slide, using the same 1/4″ endmill.

Then I replaced the endmill with the Brownells 60 degrees cutter and finished the cut in one pass, moving the table very slowly and using a lot of cutting oil.

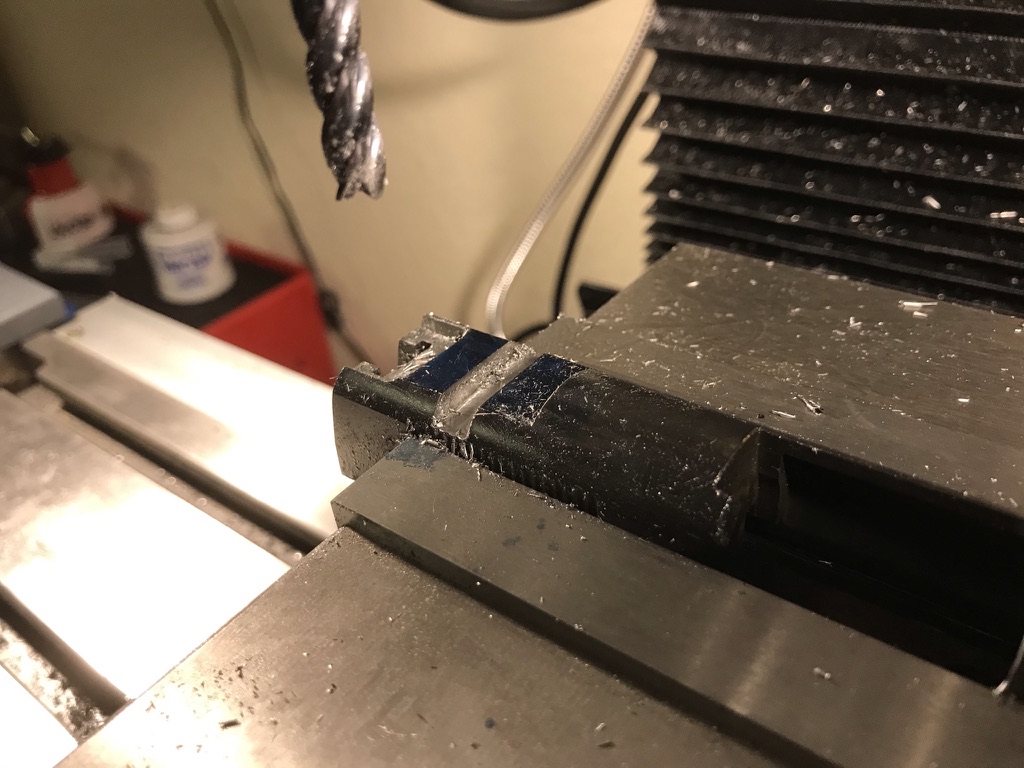

The dovetail is undersized and the dimensions are not 100% precise, so after the machining it took a lot of hand filing and fitting. The cross cut I made was a bit too deep so I silver soldered a piece of metal and filed it down until the base was snug fit.

Next I located the hole for the elevation screw, drilled with #32 bit and tapped with 6-48 tap.

OK, the rear sight is done, on to the front sight!

This was much easier – I simply measured the sight from the middle of the base to the front end and added another 0.03 to step back from the edge of the slide, for the total of .31″ from the front of the slide to the middle of the base. Then I found the edge of the slide, came back .31″ and cut across the slide with 1/4″ square end mill and .074″ deep. Then I repeated the cut with 65 degrees dovetail cutter.

After a few passes with 65 degrees file the dovetail was ready for a snug fit!

I’m going to refinish the slide later, so I didn’t drill the hole for the pin that holds the sight in place. I hate fiddling with tiny bits so maybe I will solder it in place instead or use a Loctite.